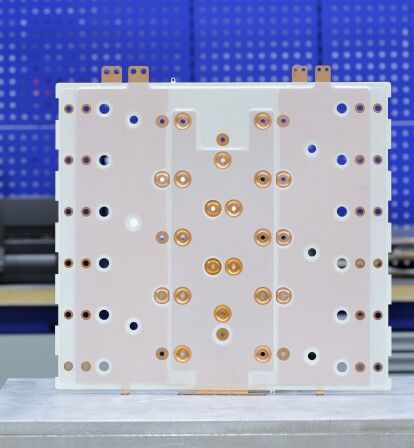

Aluminium & Copper Lamination Services: Laminated busbars and other power components

Laminated busbars made of copper and aluminum busbars are an Electris speciality service.

Laminated copper and aluminum busbars are an Electris speciality.

We are one of few companies in Europe to have developed a process for lamination of electrical bus bars.

Laminated bus bars are components consisting of layers of copper separated by a thin dielectric, laid up to form a uniform structure. Thanks to the bus bar lamination process, each copper layer is suitably insulated, so that conductive elements with different potentials are electrically separated from each other. The main purpose of manufacturing these technologically advanced products is to optimize electrical performance.

Our machines can make components of various shapes – from small items to ones measuring up to 650 x 800 mm. We can manufacture one-off pieces, as well as large series of laminated bus bars. For your benefit, we also provide adequate HV (30 kV) and PD voltage tests to ensure the right quality of the products.

The use of adequately laminated bus bars ensures space-saving installation in switchgear or control cabinets, easy assembly, and high work efficiency. At high current loads, laminated busbars perform much better than cables or wire conductors.

Benefits of laminate power components:

- Space-saving: compared to power electronic equipment connected by wiring, bus bars save much more space.

- Easy to install: electronic systems or components are mounted directly onto the laminated bus bars. This makes installation easy and the whole plant convenient to maintain, which in turn reduces production and maintenance costs.

- Improved electrical properties: reduced inductance and impedance – high capacitance distribution ensures low characteristic impedance, while the increased surface and cross-sectional areas ensure low inductance.

- Improved current carrying capacity: laminated busbars have a larger cross-section and can provide increased current carrying capacity.

- Improved thermal performance: larger surface areas provide better heat dissipation and thermal radiation.

Thanks to the latest and technologically advanced processing machines and the expertise of our engineers, we can design and produce extremely high quality in our laminated components.

We will turn your concept into a finished product, complete with the right documentation.

We manufacture components and supply them to companies in many sectors.

We would be happy to

discuss your needs.

Write to us so that we can prepare

a dedicated proposal for you. Ask for a quote.